Mike – – The first picture is the original companionway door on our Beneteau Limited Edition 37. The door was easy getting in but when it was shut, getting out was very difficult. The second picture is the completed installation of the new doors. Your doors are well built, nice looking and make it very easy to get in and out. My wife and I thank you. Jim

DIFFERENCES IN WORKMANSHIP DESIGN AND PRACTICES

I like to talk about workmanship practices, quality of materials, and design philosophy. Under workmanship practices all hinge flaps and screws are hidden except the barrel of the hinge. Hidden hinges denote an elegant approach to any construction by caring about your technique and installation. And yes it costs more. The aesthetic gain is well worth it. Also under good practices all drain holes for any possible water intrusion around the glass or screens are hidden through the center section of the bottom rail and exits right at the bottom sill plate that the door rests on. While this also costs more it denotes good workmanship again by not having to look at dirt stains streaking down the front of your doors.

Under quality of materials and design philosophy only solid materials either 7/8 for teak or 3/4 for plastic are used. No laminates are employed to create pockets for inserts as inserts are not employed in the designs. They severely weaken the frame. Rather the screen option is installed full time and the window is lifted to expose the screen. Not having a screen insert to store means not having to find it with a hole through it later.

At the center section where the doors meet the old time tested method of having a weather strip is employed. It is 3/4 thick by 1 3/4 wide for the full height of the door. This allows for a 7/8 over lap to keep the weather out. So the doors are already 3/4 minimum thickness plus 3/4 for the weather strip for a total of 1.5 inches. This is in sharp contrast to a 3/8 rabbit leaving only a 3/8 by 3/8 lip as the structural entity not only keeping the weather out but keeping one door from buckling past the other.

Later I will talk about material qualities as they relate to strength, durability. and weight. After that we will take a long look at locking mechanisms and approaches.

Here is a link and video by Joe Cicero:

Mike

KEEPING UP

There is no doubt that keeping up on only custom installations from Companionway Doors to exotic inlay in tables makes it difficult to supply in a time frame that you would normally expect from items on the shelf. Then again that is said with a slight of hand with respect to trying to fill all of the orders that may be in process all at one time. I ask all the time in Fall to please order now. Yet while March seems well in advance of any reasonable lead time, it only takes degree sales activity to increase lead times dramatically. I do take responsibility for this and juggle the best we can to satisfy everyone’s individual requirements. At some point I paint a light minded picture by portraying the old triangle of FAST, GOOD, and CHEAP. You may have it fast and cheap but not good. You may have it fast and good but not cheap, and lastly you may have it good and cheap but not fast. Well none of that is fair, so I try to be a good communicator with my customers and that is my best asset after the quality.

Thanks to all of you for a great year,

Mike

CATALINA YACHTS AND PRIDE OF OWNERSHIP

Last time I went to the all Catalina Rendezvous for Western Canada many years ago I was reminded how died in the wool I was with Catalina when asked who had had the most number of Catalinas for a door prize. With five to name off, 22, 27, 30, 36, and 380 blurted out, there for a moment embarrassment is what I felt as if having been greedy. Yet it was really pride and passion that had propelled my business as Teak Concepts and Cruissing Concepts. Knowing these boats intimately and sailing them for almost 40 years now keeps me proud of ownership for both the boats and the business. I hope it shows when ever you talk to me.

Thank you,

Mike

GRATING SYSETEM FOR COCKPITS

FLOORBOARDS

COCKPIT FLOORS

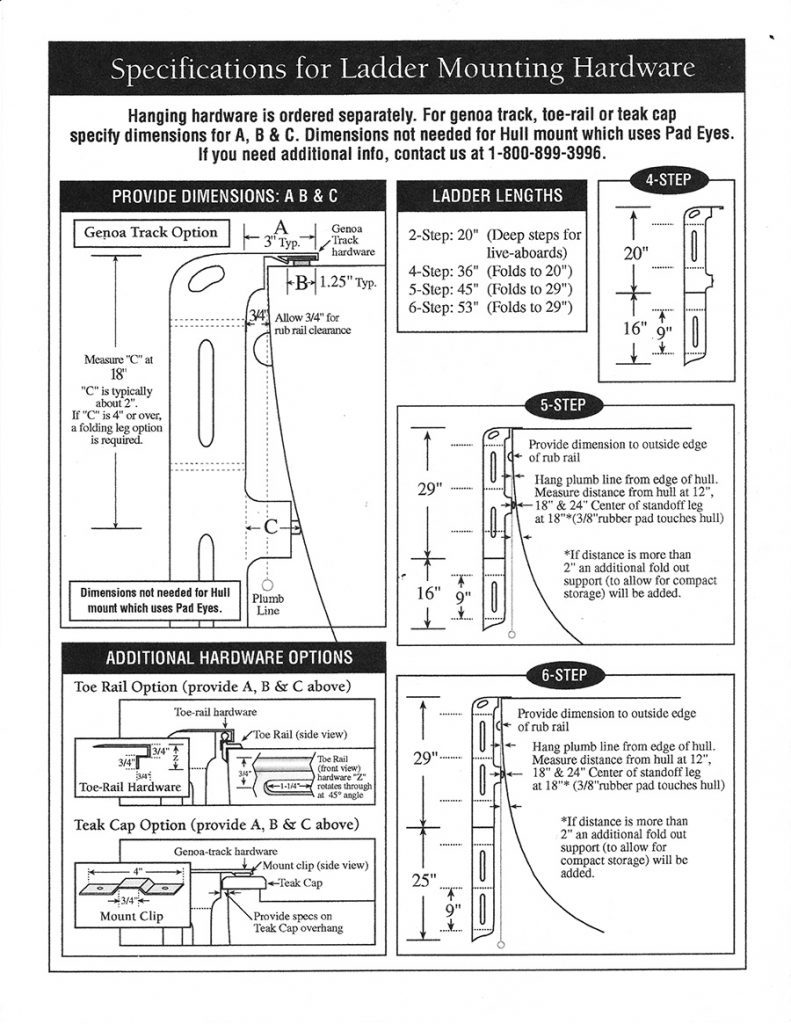

BOARDING LADDER FOR AN ISLAND PACKET COMPLEMENT

KEEPING UP

OIL FINISHES FOR TEAK

In preparing for oil finishes I use Daly’s Seafin “Ship N Shore” penetrating oil before any other finishing. After sanding I apply a soaking coat and wait 30 minutes before applying a second coat. The first coat is usually absorbed entirely. The second coat sits on the surface mostly and makes sure that all areas have been liberally treated. After another 30 minutes the second coat is wiped back without streaks and racked to dry for several days. Drying may be determined be placing the palm of your hand on the surface once a day until it no longer feels cool to the touch. Sometimes 3 to 4 days is required before the next step.

The ladder has allowed us to climb in and out of the dinghy securely and having both boats protected with regular fenders hung on both sides of the ladder. Problem solved!

The ladder has allowed us to climb in and out of the dinghy securely and having both boats protected with regular fenders hung on both sides of the ladder. Problem solved! in tables makes it difficult to supply in a time frame that you would normally expect from items on the shelf. Then again that is said with a slight of hand with respect to trying to fill all of the orders that may be in process all at one time. I ask all the time in Fall to please order now. Yet while March seems well in advance of any reasonable lead time, it only takes degree sales activity to increase lead times dramatically. I do take responsibility for this and juggle the best we can to satisfy everyone’s individual requirements. At some point I paint a light minded picture by portraying the old triangle of FAST, GOOD, and CHEAP. You may have it fast and cheap but not good. You may have it fast and good but not cheap, and lastly you may have it good and cheap but not fast. Well none of that is fair, so I try to be a good communicator with my customers and that is my best asset after the quality.

in tables makes it difficult to supply in a time frame that you would normally expect from items on the shelf. Then again that is said with a slight of hand with respect to trying to fill all of the orders that may be in process all at one time. I ask all the time in Fall to please order now. Yet while March seems well in advance of any reasonable lead time, it only takes degree sales activity to increase lead times dramatically. I do take responsibility for this and juggle the best we can to satisfy everyone’s individual requirements. At some point I paint a light minded picture by portraying the old triangle of FAST, GOOD, and CHEAP. You may have it fast and cheap but not good. You may have it fast and good but not cheap, and lastly you may have it good and cheap but not fast. Well none of that is fair, so I try to be a good communicator with my customers and that is my best asset after the quality.